The Mission: Use every single machine in the Boston University makerspace to build a rotary vane pump

The Process:

Lathe - Boring, Drilling, Shaving, Reaming

Mill - Cutting hex head end of shaft and Delrin vanes, tapping threads into housing

Sweat-fitting

Removing burrs

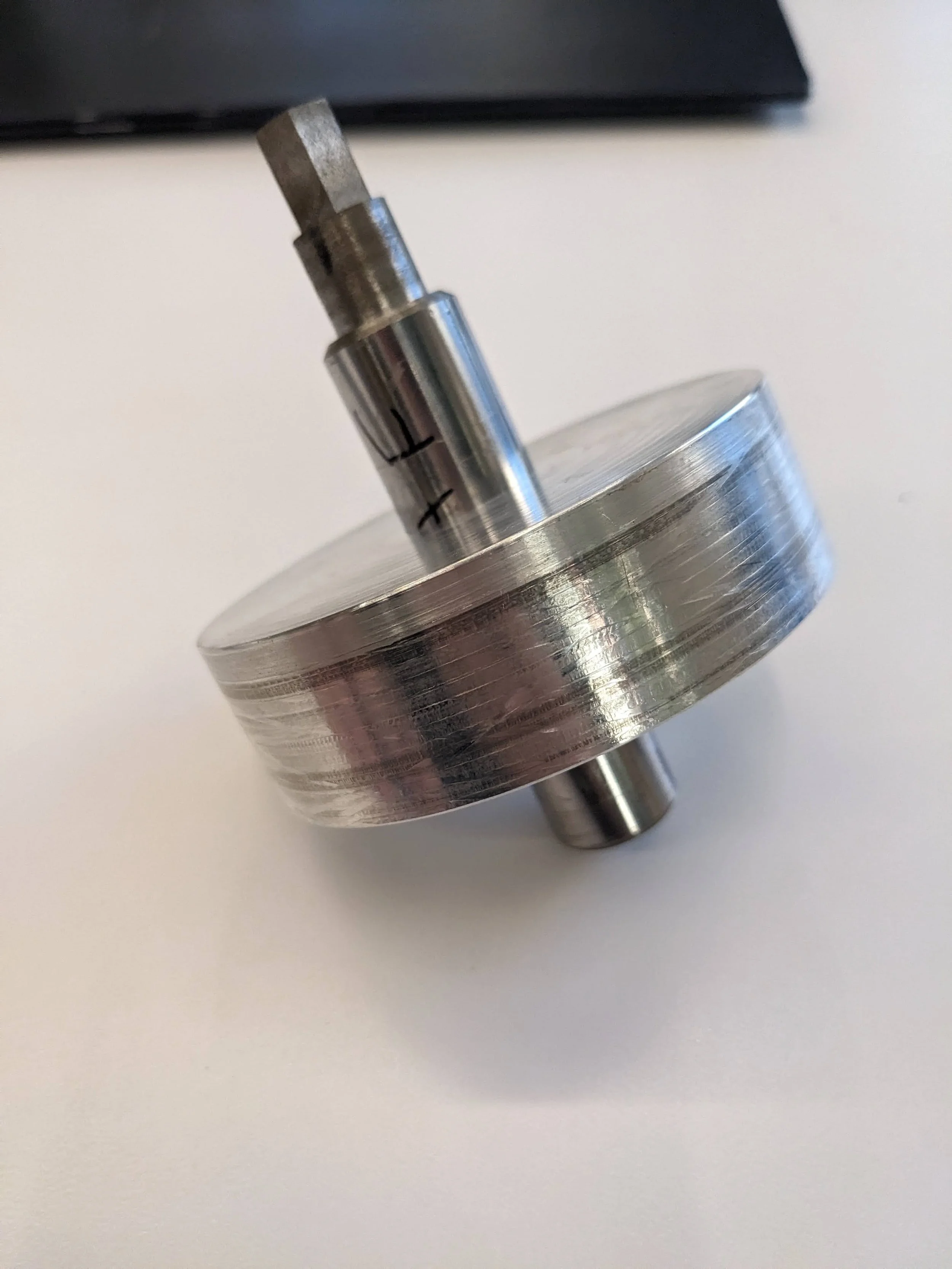

After lathing, boring, and reaming: a future rotor!

Before sweat-fit

After accidentally breaking the sweat-fit the night before the pump was due. The video footage was too tragic for me to keep, but imagine the shaft turning freely in the rotor.

(Don't worry, I fixed it later)

Measuring the slots to find dimensions for the Delrin vanes

Using wire EDM to saw off the exposed end of the pin driven through the rotor and shaft to hold them together

SUCCESS!

After milling: a shaft!

Taking the pump to the bike shop and borrowing the bearing puller to remove an overpressed bearing

Finally….

After sweat-fit